Info

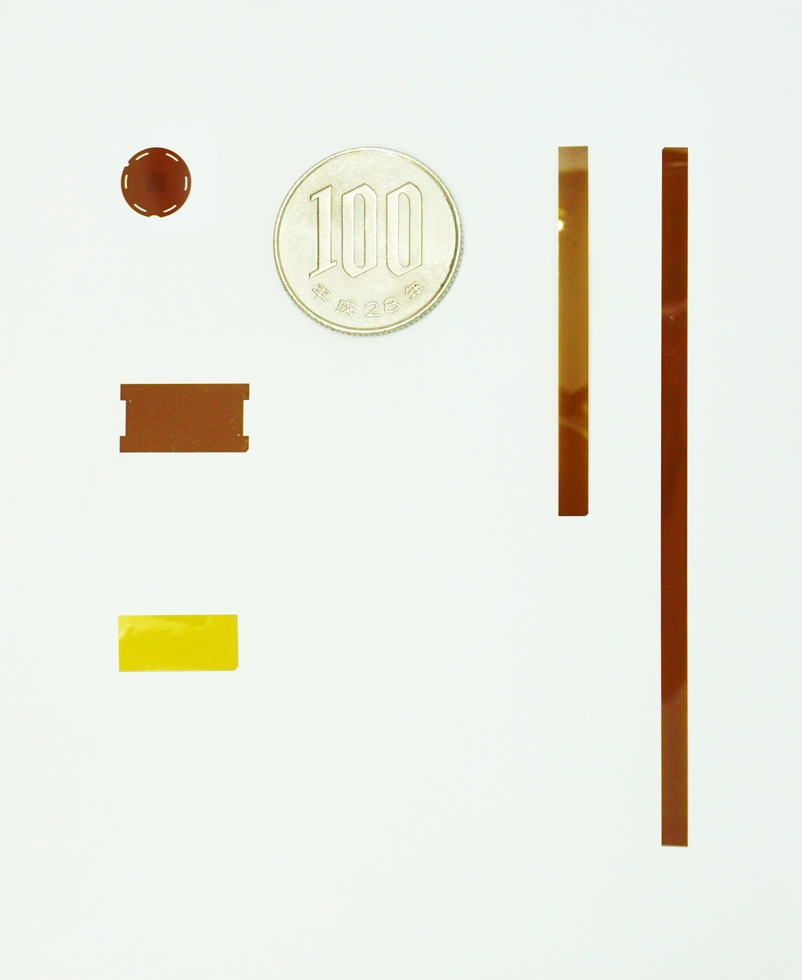

Offering scalable production up to 12 cm.

Offering scalable production up to 12 cm.

•The edge of the nozzle hole is flat, and it is not easy to residual ink

•It is not easy to cause elastic fatigue, and consistent in ink output

•Good bonding effect, so it is especially suitable for the processing of ink cartridges with different materials

Experience in laser drilling, laser cutting, and measurement system of automatic/semi-automatic process.

Deeply cultivated in excimer laser fine precision machining for more than 20 years.

Using the stable laser source, a major American manufacturer “Coherent”, and a high-precision platform made by a major Japanese manufacturer,

Through the core technology of high-end excimer laser micromachining,thousands of tiny holes of 3 microns are precisely drilling on the polymer plastic firm within a diameter of 2 mm area.

More than 80 million mesh have been produced. Apply to in consumer electronics, beauty products, and medical products.

| Tool | lKrF Excimer laser for 2D/3D structuring |

|---|---|

| Nikon NEXIV VMR Vision Measurement System | |

| DPSS 266nm Laser | |

| Material | Polymer, PoIyimide, PMMA, PC and Photo-resist |

| Shape | Drilling, Grooving, Cutting and Structuring |

| Quality | Dimension Accuracy:< 2 μm |

| Position Accuracy:± 3 μm | |

| Ra < 0.05 μm |